Do You Know Which Warehouse Lighting You Need?

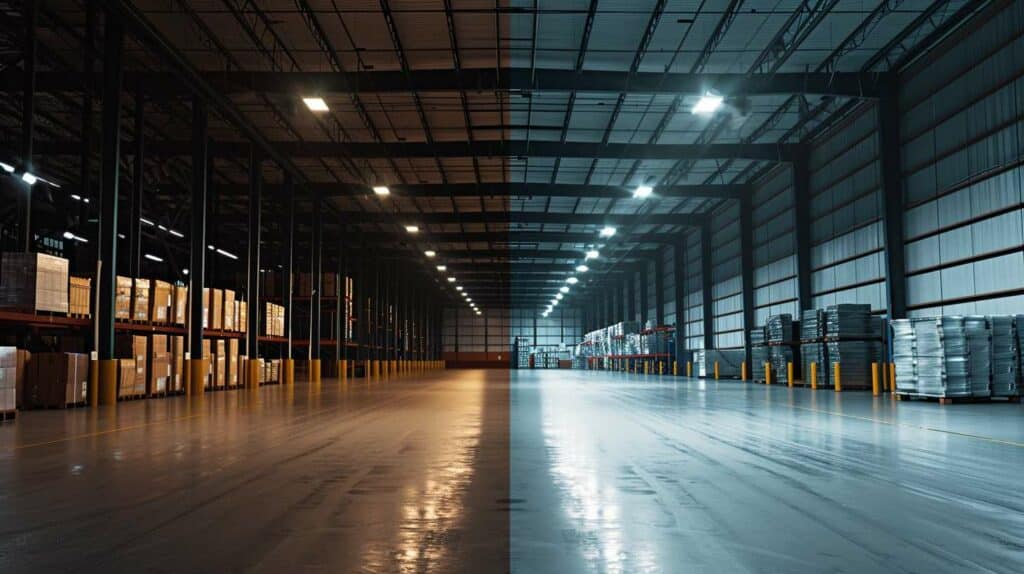

Illuminating Your Warehouse: A Comprehensive Guide to Lighting Solutions

Choosing the right lighting for your warehouse can seem daunting, but it doesn’t have to be. Let’s break down the key factors to consider when planning or upgrading your warehouse lighting system.

Selecting the Perfect Light Source

When it comes to warehouse lighting, you’ve got three main contenders:

- High Intensity Discharge (HID): The old reliable with the lowest upfront cost. However, they’re not without drawbacks:

- High lumen depreciation rate

- Limited color temperature options

- Warm-up time required

- Cool-down period needed before restarting

- Fluorescent: A budget-friendly, energy-efficient alternative to HID:

- Wide range of color temperatures (2700K to 6500K)

- Various sizes and shapes available

- Performance issues in extreme temperatures

- Lifespan affected by frequent on/off cycles

- LED: The champion of energy efficiency and versatility:

- Lowest energy consumption

- Comparable or better lumen output

- Long lifespan (up to 100,000 hours)

- Excellent performance in cold temperatures

- Minimal impact from on/off cycles

Brightness Matters

The brightness of your fixtures depends on several factors:

- Ceiling and wall colors (lighter colors reflect more light)

- Presence of skylights

- Specific area requirements

Pro tip: Consider diffuser lens covers to reduce glare and improve workplace safety.

Color Temperature: The Productivity Booster

For warehouses, aim for color temperatures between 4000K and 5000K. This cool white light has been shown to reduce eyestrain and boost productivity.

Light Distribution: Tailoring to Your Space

Choose between two main distribution types:

- Type I: Long, narrow pattern ideal for spaces with tall shelving

- Type V: Wide, circular or square pattern perfect for open floor plans

Strategic Fixture Positioning

Avoid hot spots and dark areas by carefully planning your fixture layout. When in doubt, consult a lighting professional.

Energy-Saving Add-Ons

Consider incorporating occupancy or vacancy sensors to reduce energy waste by up to 30%. These smart devices ensure lights are only on when needed[1].

By considering these factors, you’ll be well on your way to creating an efficient, well-lit warehouse space that enhances productivity and safety. Ready to illuminate your warehouse like a pro? Let’s make it happen!